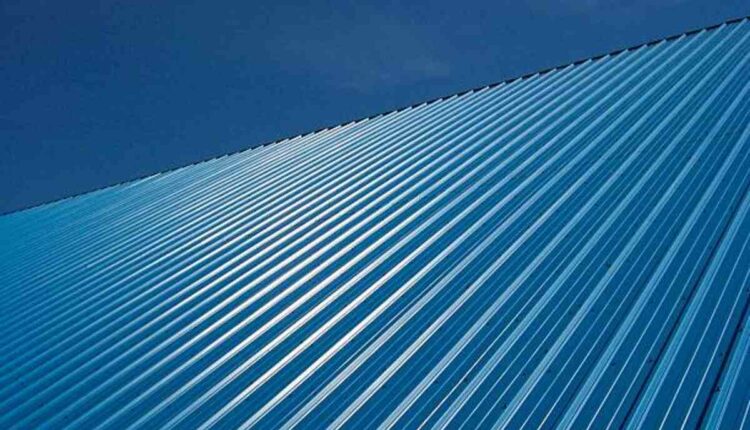

Roof Coatings for Metal

A metal roof might be difficult to protect from the elements. The surface’s continual expansion and contraction is one of the most critical variables. A metal roof can expand and contract by up to 2 inches every 100 feet, which can be catastrophic to fasteners and seams, which account for 90% of all roof leaks. Choose the best metal roofing suppliers.

Suppose you need help with a metal surface. In that case, you have two options: replace the roof, which may be incredibly expensive and time-consuming, or repair it with an elastomeric roof coating, which can be much cheaper than replacing the roof.

A high-quality elastomeric roof can extend the life of your existing roof by many years. They come in many forms, but the high-quality ones are generally more expensive and should be the sole option. Lower-cost coatings also do not stretch and rarely have adequate UV protection built in.

Another essential aspect of Elastomeric coatings is the energy savings they provide. For example, the temperature of the metal roof surface might drop by 40 degrees or more in a concise amount of time after covering it. Reducing heat transmission from your roof will keep your building substantially more relaxed and lower your energy expenses.

However, the coating does not function in isolation; other procedures must be taken to guarantee that your construction is effectively sealed from the elements. The first step is establishing a clean surface, which should be accomplished using a high-powered pressure washer to eliminate difficult-to-remove roof scum.

Next, go over the roof and spray all rusted spots with an inhibitor to prevent future metal corrosion. You should then walk around and reinforce any roof penetrations with elastomeric roof cement, including pipes, air ducts, fan units, and any other spots where something is entering through the surface. It would help if you also reinforced or replaced any existing roof flashings running around the roof.

After the surface has cured, the next step is to seal the fasteners individually with a rivet guard-type material and replace any missing pins. Following this, you must individually seal each seam with a seam guard, usually a rollout tape, a relatively thick elastomeric cement, or a combination of the two depending on the product.

Finally, you can apply the final roof coating to complete the process. You’ll need a roof coatings sprayer, which you can get from a paint store; just be sure you replace the sprayer head with the correct size for your roof coating. Depending on the product, you may need to apply a priming coat before two coats of finish roof coating material. Ascertain that the roof surface is dry and that rain is not expected for the day you plan to finish the roof.

The elastomeric coating will not adhere to a damp roof surface, so ensure it is clean and dry. Temperature is also a significant consideration; the roof coatings should be applied at temperatures not below 55 degrees Fahrenheit to ensure appropriate curing.

That is how you would seal your metal roof. Of course, you should employ a qualified roof coatings professional to conduct the process, but if you want to save money, you can do it yourself.

Read also: Eclectic Home Decor

Comments are closed.